Standard process in regard to the PPAP(Production Part Approval Process)

for design and development has been built according to characteristics

and systematic management has been conducted

to secure the world-class product competitiveness

Through this organization quality control system,

Nextchip has built the infrastructure for securing ability to achieve the internalization,

process-centered management program and constant process improvement activity

Asset library and establishment of process according to the sustained growth of corporation has been built

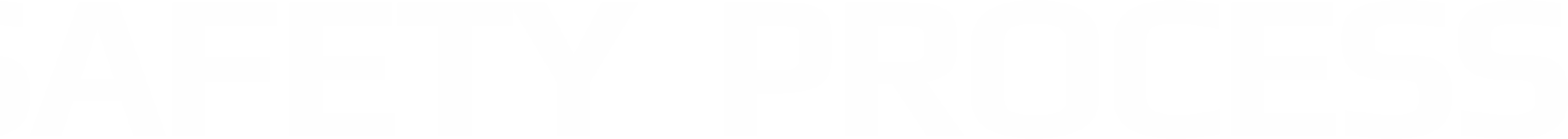

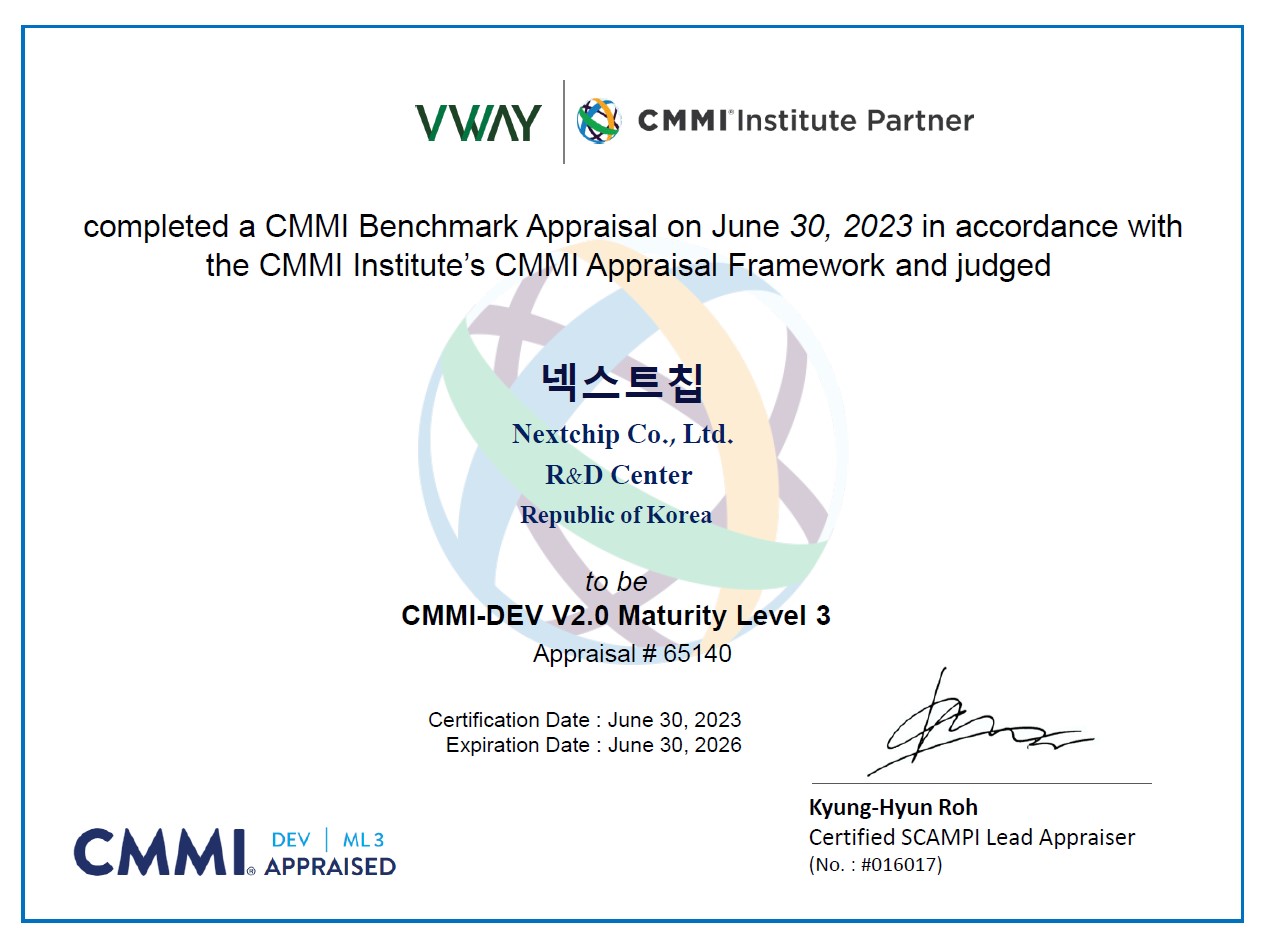

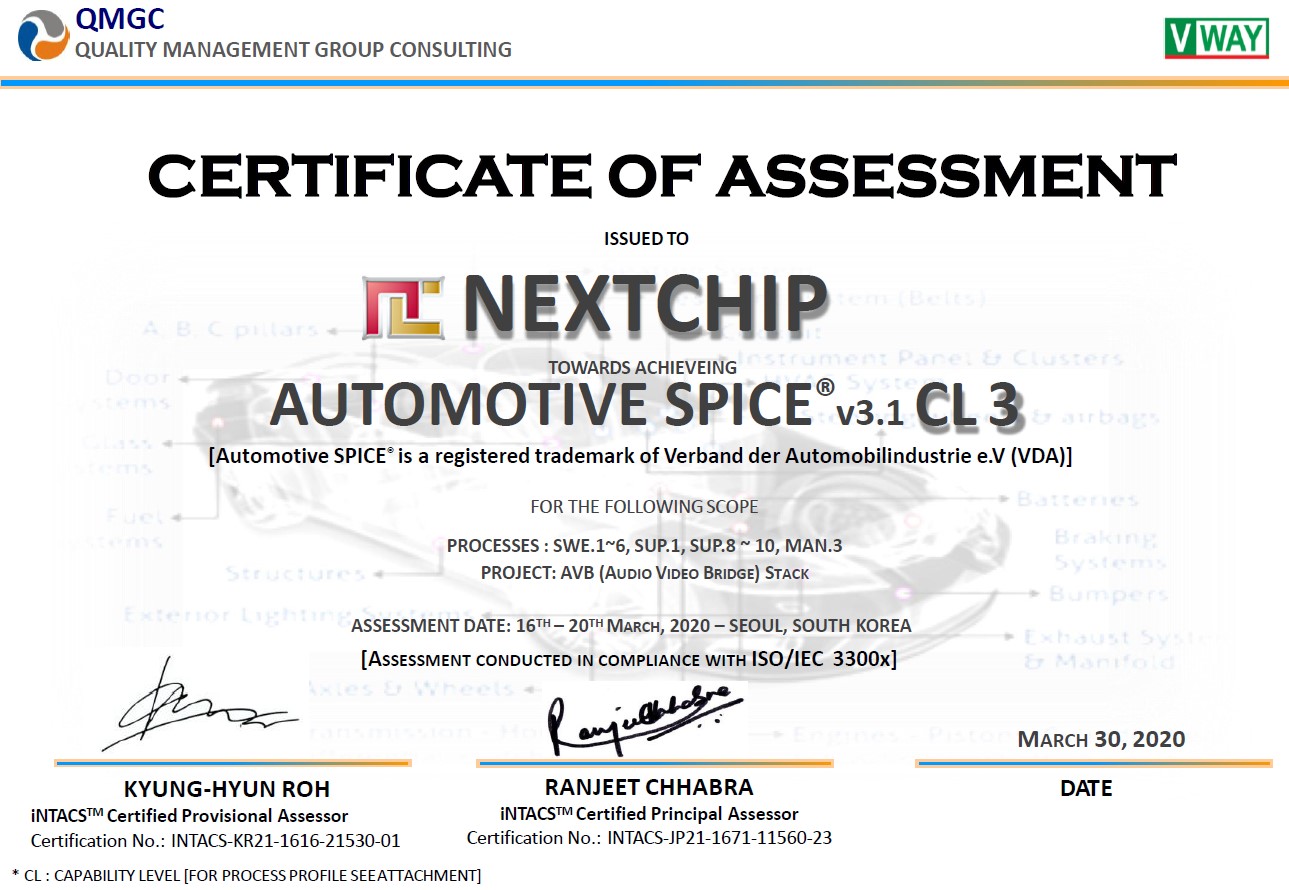

Internal : ISO9001/14001, CMMI DEV 2.0 LV3, ASPICE V3.1 CL3, ISO26262 FSM ASIL D capable

External : ISO/TS16949 management